This is the most labourous pattern, the treadle sequence is so long but i am nearly at the end. Its an eight shaft pattern.

Spinning and Weaving with Cutie 'n' Me

Weaving, spinning, knitting , crocheting , painting, woodwork just about anything craft minded that you could think of.

Wednesday, 15 May 2024

Friday, 18 June 2021

Outdoor Cushions Finally Woven

I have been planning these cushions for at least 2 years but life got in the way. I was determined to weave them this year and now they are finally finished. I am extremely happy with how they have turned out.

I put on enough warp for 6 of them. I knew from my last cushions that the 5/2 cotton i have been using shrinks by about 3 inches after hot washing and running the fabric through the dryer, so I added about 2 more inches to my warp calculations .

The pattern that I picked is from somewhere on Pinterest and looked very busy on Paper but I put it into the iWeaveIt app and played around with the colours that i would be using and it ended up looking really nice. I chose Black and brown with a black weft.

Once again i used woven interfacing on the back of my fabric and finished with an invisible zip .

Here is my lovely new cushions.

Project notes

5/2 Mercerised Cotton.

22 in wide in reed

440 ends

20 ends per inch

4 Meter warp

Finished size before washing 19 1/2 inches

After washing 18 1/2

Thursday, 17 June 2021

2 special cushions for my newly renovated home

I chose to do these cushions in a 4 shaft diamond design from the handweavers pattern directory book. I love how they turned out in 5/2 mercerised cotton. I used a woven interfacing on the back of the woven fabric to give it a nice stable finish.

Lovely and plump and very soft to touch. What i was not happy with . was Ashfords cotton especially the white having so many knots in it . That really annoys me because i am having to cut so much length out of my thread that i have paid dearly for. The softness of the finished fabric on the other hand is beautiful.

Here they are all finished, plump and sitting proud. This lounge isn’t the colour that i was making the cushions for, its for my upcoming lounge after our very long reno that is now completed.

Kitchen Towels completed

I got 8 kitchen towels out of this warp. I love the way they turned out. Here they are in all their glory.

I used 8 different drafts in a straight 8 design and its so lovely to sample all the different drafts that this simple weaving produces on eight shafts. They were all made in 10/2 mercerised cotton and are very absorbent.

Saturday, 17 April 2021

Monday, 29 April 2019

Singer LK 150 Knitting machine

My interest grew to a second machine another singer but this time one with a ribber. That took a lot of learning and stuff ups but I finally use it and it knits beautiful ribs. Both of these machine are standard gauge .

I longed to knit with the yarn I have so much of Australian 8 ply so I started searching again and came upon a 1980 Singer LK150 . I love it. It may not do all the special things that the punch card machines do nor ribbing but who cares I can make lace manually, rib manually and of course garter stitch is another story.

I have knit this summer top the lace part done on the machine and the top part by hand.

I really enjoy doing the lace.

My big wish is to be lucky enough to find another second hand one so I can knit slightly larger projects. If anyone has one please feel free to contact me.

I haven't given up on my weaving or spinning i have just diverted for a while.

Thursday, 17 May 2018

Weaving Summer and Winter Sheep

I have been wanting to try this technique out simply because I hadn't done it before.

I took a look at the draft again that was on her blog and started to plan. It has 12 treadles, nope I didn't have 12 treadles so I used my table loom .

Next step turn it into a lift plan, again something I had done before but it wasn't difficult at all. There is always a solution to a problem.

My table loom is an 8 shaft jack table loom , levers that raise the shafts , and I think it was made by a manual arts school down in N.S.W.

I have since seen one since on Gumtree called a Pagett loom which looks exactly the same as mine, but can't find any information on that.

The built in removable raddle on the back beam.

The levers are in the centre

and hanging shafts with springs on the bottom of every shaft 1 either side of each shaft.

It has metal heddle rods and metal heddles.

It has a 12 dent reed.

Okay I have enough shafts and I only have to worry about which shaft has to be lifted. So all is good there.

I put the draft into a weaving app but had trouble making it into a lift plan. I also tried the demo version of fibreworks and still it wasn't what I was after. So out with the pens and did it by hand.

I also drew up the threading plan for 1 whole repeat, counted how many heddles would be needed on each shaft and made sure i had enough and thankfully i did.

This is a fun pattern and rewarding to watch weave on my loom.

What I am going to make out of this fabric I have no idea at this point. Update i still have made nothing out of this fabric yet. I wonder what i could make and for what purpose would it end up being for.

Tuesday, 24 April 2018

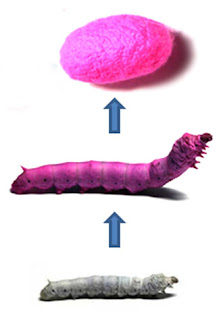

Silkworms and coloured Silk

This image is from australian geographic's site from the article I have added a link for.

Here is the video

http://www.australiangeographic.com.au/news/2011/03/silkworms-made-to-spin-coloured-silk

https://onlinelibrary.wiley.com/action/downloadSupplement?doi=10.1002%2Fadma.201003860&attachmentId=184340639